UAE – Pollution Fine for Soot Discharge from Ship’s Inert Gas Systems at the Port of Fujairah

Fujairah is a major port in the United Arab Emirates and subject to strict environmental regulations aimed at reducing the impact of shipping on the local environment. Under these regulations, ships must comply with specific emissions standards and may face fines for exceeding them. The emission standards cover various pollutants, including sulphur oxides (SOx), nitrogen oxides (NOx), particulate matter (PM), and volatile organic compounds (VOCs).

The Club regularly receives claims for pollution fines in Fujairah for soot discharge from the ship's inert gas system. The average fine amount levied for such infringement by the authorities is USD 50,000 per incident.

When a soot discharge from the inert gas system has occurred, the port authorities will be levying the fine because they deem the ship exceeds the PM emissions standard and is further contributing toward the overall air and water pollution that impacts the local ecosystem and wildlife.

The inert gas system on a ship is designed to prevent the build-up of explosive gases in the cargo tanks by reducing the oxygen to a level where an explosion cannot occur. It is achieved by supplying inert gas to the cargo tanks.

Making inert gas on a ship requires fuel oil to be burnt with low excess air in a boiler or dedicated inert gas generator. Subsequently, efficient combustion depends on good atomization/fuel spread when burning fuel with low excess air.

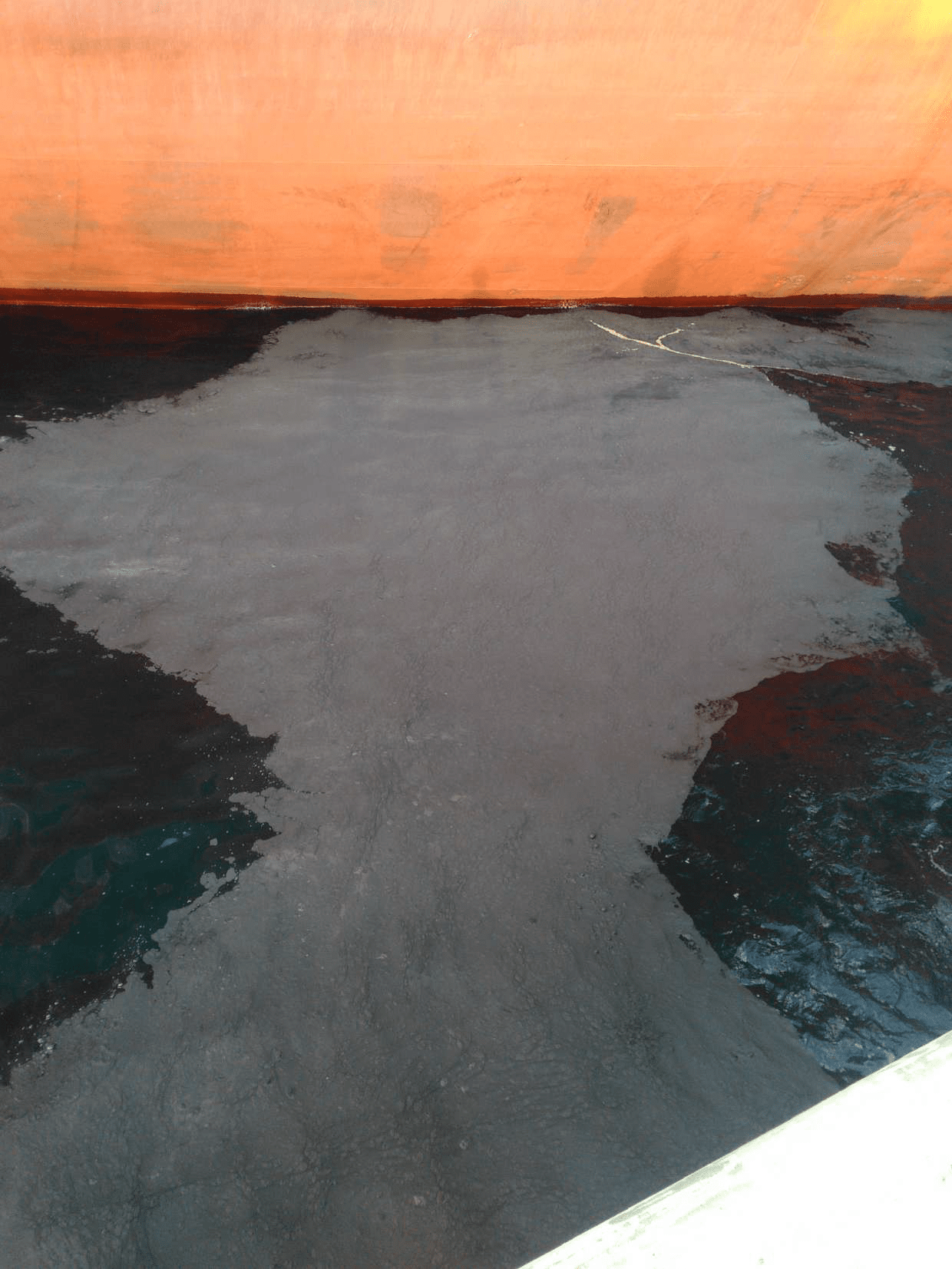

If fuel atomization is poor, then incomplete combustion may result with low excess air levels. As the exhaust gas is washed and cooled in the inert gas scrubber tower, unburnt fuel or soot may enter this water and can be discharged overboard in the scrubber wash water, thus leading to pollution.

If the ship's inert gas system is discharging soot from the cooling water outlet, it could be an indication of several issues, such as:

- Fouled scrubber tower: The build-up of deposits in the scrubber tower can reduce the heat transfer efficiency, leading to higher exhaust gas temperatures and a higher likelihood of soot formation. Regular maintenance and cleaning of the scrubber tower can help prevent this issue.

- Improper fuel combustion: The fuel-air mixture in the combustion chamber may not be properly adjusted, leading to incomplete combustion and the formation of soot. This can be addressed by adjusting the combustion parameters and ensuring proper fuel quality.

- Insufficient cooling water flow: If the cooling water flow rate is too low, the scrubber tower may be unable to remove enough heat from the exhaust gas, leading to higher exhaust gas temperatures and soot formation. Checking and adjusting the cooling water flow rate can help address this issue.

- Overloading of the inert gas system: If the ship's inert gas system is overloaded, it may be unable to effectively cool the exhaust gas, leading to higher exhaust gas temperatures and soot formation. Properly sizing the inert gas system and avoiding overloading can help prevent this issue.

Consequently, because of the potential outcomes that can arise and to ensure compliance with emissions standards and environmental regulations, we would remind Members with inert gas systems on their ships to ensure that they are maintained in good working order and to take measures to address these issues through proper maintenance and operation to prevent soot formation and ensure safe and efficient operation of the inert gas system.